Activated Roller Belt (ARB Conveyors) & Integerated Roller Belt

ARB or Activated Roller Belt™ is known in the conveyor industry as the patented Technology made by Intralox®. Additionally, Multi-Conveyor may source other roller belting options based on project requirements. Your individual application determines which technology is best suited to transfer, divert, sort, align, turn, or merge your products. Roller belts use free-spinning angled rollers or spheres vector speed direction to uniquely transfer and divert packages. Multi-Conveyor also incorporates other roller top brands and styles for various applications.

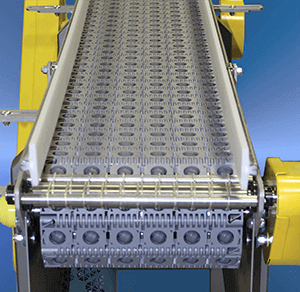

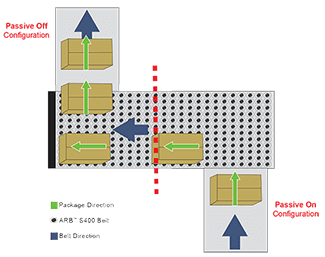

ARB rollers extend above and below the belt surface and are positioned at an angle in relation to the direction the belt travels. ARB rollers that are activated by wear strip or helix rollers below the chain move products at a vector angle across the chain in the direction of roller orientation combined with the direction of belt travel. Ninety degree (90º) passive-off and passive-on transfers are also available and do not require any activation. Systems using ARB conveyors can change the direction, alignment, location and speed of an item independently without using rails or complicated mechanical controls. Multi-Conveyor designs and manufactures equipment using Intralox ARB technology, and Intralox DARB technology when higher speed sorting, diverting and more difficult to handle packages.

ARB rollers extend above and below the belt surface and are positioned at an angle in relation to the direction the belt travels. ARB rollers that are activated by wear strip or helix rollers below the chain move products at a vector angle across the chain in the direction of roller orientation combined with the direction of belt travel. Ninety degree (90º) passive-off and passive-on transfers are also available and do not require any activation. Systems using ARB conveyors can change the direction, alignment, location and speed of an item independently without using rails or complicated mechanical controls. Multi-Conveyor designs and manufactures equipment using Intralox ARB technology, and Intralox DARB technology when higher speed sorting, diverting and more difficult to handle packages.

As one of the leading roller top chain conveyor manufacturers, Multi-Conveyor incorporates these licensed, certified, and/or officially trained roller belt technologies on our equipment. We bring the benefits of modular plastic belts to complex package handling processes like sorting, merging, and aligning even small items. The result is a simplified, safer, cost-effective solution for product orientation and control. Note: Multi-Conveyor is also a licensed supplier of ModSort integrated roller belt technology.

Roller Belt Conveyors for all angles

Align: The alignment conveyor drives a smooth stream of product to one side uniformly and gently squares them against a guard rail. Products can be directed using angled rollers embedded in the conveyor belt, allowing product quality to remain intact.

Right Angle Transfers: Roller belting can be used for simple right angle transfers but it can also be used for diverting to either side at a variety of angles.

Sort: Sorters are capable of bi-directionally dispersing products at various angles. This unique capability successfully handles products of various sizes within a limited footprint.

Case Alignment and Turning: Multi-Conveyor uses angled roller belts to redirect cases and turn them in a general uniform fashion. Case aligners are often used in conjunction with bar-coders and labeling for packaging lines. Case turners using this technology typically need fewer moving parts and fewer drives.

Diverting and Merging, Horizontal Transfers: For diverting, merging, and 90º transfers, belting with rollers embedded into the surface offers a smooth merge or repositioning of product from multiple lines into single file. Belting with omnidirectional spheres allow for exceptionally small packages to be diverted on the fly or at 90º in a full stop and divert mode.

Single Filing: Roller belt conveyors can move products from side-by-side orientation into single-file and typically reduce product jams or sorting inaccuracies.