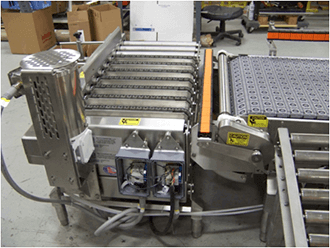

Stainless Steel Conveyor Construction

Stainless steel conveyors or devices are specified based on criteria such as washdown environments, sanitary requirements for food or pharmaceuticals, and chemical or corrosive product processing. Different finishes are determined by moisture levels and bacterial growth concerns. Stainless steel is the number 1 choice for food grade conveyor systems.

Stainless steel conveyors or devices are specified based on criteria such as washdown environments, sanitary requirements for food or pharmaceuticals, and chemical or corrosive product processing. Different finishes are determined by moisture levels and bacterial growth concerns. Stainless steel is the number 1 choice for food grade conveyor systems.

Our standard stainless steel conveyor frame is made from 11 ga (vs. a lower 12 ga.) thick material. We provide 2BN, #4 and #8 polish finish. The 2BN finish is used for applications where there is direct food contact. This is considered a sanitary finish. Sanitary welded designs are 7 ga. 2BN. In contrast, our low-profile, small transfer Slim-Fit line requires #8 mirror finish. No skimping on quality materials here at Multi-Conveyor!

The #4 polish is actually a ground polish finish. It is used mostly for appearance. Because the #4 polish is ground into the steel, it leaves tiny grooves that could possibly collect bacteria. Our newly introduced Slim-Fit™ with #8 polish has a "mirror look" for the utmost in sheen, durability and wear.

All of our stainless steel conveyor systems can be built to food-grade, agency-approved (USDA, FDA all the way to 3A certification) compliance based on our your application's requirements.

For Mild Steel Constructed conveyors that do not require wash down, please click here.

Let us know if we can provide more information. Just click here.

Frequently Asked Questions About Stainless Steel Conveyors

What industries use stainless steel conveyors?

Stainless steel conveyors are used in many industries such as foods, beverage liquid filling, pharmaceuticals, chemical and where corrosive resistance is required.

How do you maintain cleanliness of stainless steel conveyors?

Stainless steel conveyors are designed to be pressure washed or CIP (clean in place). Chemical cleaners or other specific cleaning methods are at the discretion of the customer.

What type of stainless steel should I consider?

The industry standard is Type 304 for conveyor frames and bolt-on accessories. This metal offers broad-spectrum corrosion resistance and is cost-effective. Type 316 is another commonly used alloy that offers increased corrosion resistance in high chlorine environments.

How do you determine stainless steel conveyor sanitation levels?

Stainless steel conveyors are specified based on criteria such as wash down environments, sanitary applications such as food or pharmaceuticals and chemical or corrosive product processing. Different finishes are determined by moisture levels and bacterial growth concerns and are subject to FDA, USDA & USDA Dairy, AMI (meat), 3A Dairy, BISSC (bakery) or other compliance as required.

What does sanitary conveyor construction mean?

Premium critical radius welds, bolts and radius bushings, gasketed areas to keep contaminants from getting behind wear strips, removable NTR components for washdown including CIP (clean in place), agency approved belting to name a few. We follow strict guidelines to ensure the proper sanitary specifications are met.

Can MDR conveyors be used in a wet environment?

Absolutely! Stainless Steel MDR (Motor Driven Rollers) conveyors are available for both direct washdown and general damp duty usage. 24 volt DC motors and controllers allow simplified installations, reduced power consumption and increased operator safety. Multi-Conveyor can also provide a motorized drum pulley configured for plastic modular belts or urethane slider bed belt conveyors.