Project Management, Audits and FAT's

Our unsurpassed Project Managers facilitate your entire conveyor project from start to finish, often time adapting unforeseen equipment changes mid-stream. They are your main contact all the way up to performance FATs prior to shipment. Project Managers ensure:

- Concise approval drawings

- Clarify design and function of equipment

- Implement project scope or unforeseen design changes

- Arrange customer visits during fabrication

- Coordinate shipping and installation supervision

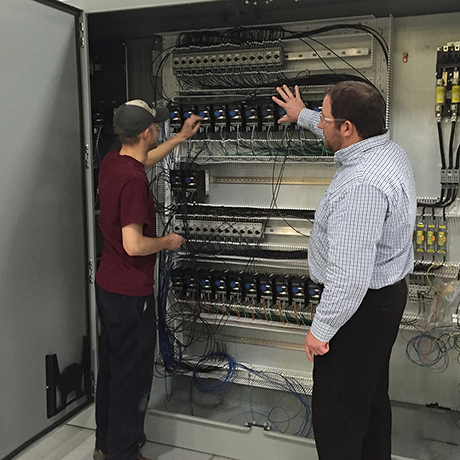

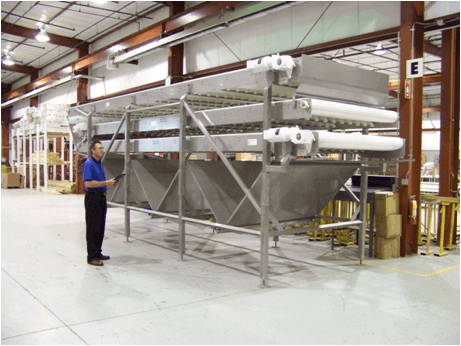

Factory Acceptance Tests (FAT) are done at our location on a regular basis by Customers, OEMs and Integrators. We encourage full equipment approval, in action, ensuring optimum performance well before we dismantle and prepare for shipment.

In many cases, after coming to an FAT, a customer may decide to tweak their conveyor or conveying device. This is generally due to their own line changes that came later in the project, or may be based on what they have seen at the FAT that they choose to adjust from their original order or requested design - prior to shipment. The fact that Multi-Conveyor is a leader in custom conveying systems, coupled with our expert team of designers, engineers and electrical wizards, we are one of the only companies that can make these changes happen when nearing completion of an already designed conveyor.

Audits can also be performed at your location to evaluate existing equipment or help in the placement of new conveyors or devices. We will come and measure the footprint of the area you need to achieve the conveying processing for that part of the line so our expert estimators and concept teams are completely aware of design parameters.

Audits can also be performed at your location to evaluate existing equipment or help in the placement of new conveyors or devices. We will come and measure the footprint of the area you need to achieve the conveying processing for that part of the line so our expert estimators and concept teams are completely aware of design parameters.

Can you say that about your current conveyor manufacturer?

Click on our latest piece of literature that explains the Multi-Conveyor advantage!