Sanitary Conveyor | Food & Pharmaceutical

... meeting critical agency compliance as required!

Our innovative Sanitary Conveyors are designed with Stainless Steel construction and are built to food or pharmaceutical industry and plant specific needs as dictated by your sanitation or food safety requirements. Designed to fit your company’s unique processing application, we will ensure you get exactly what you need.

Our innovative Sanitary Conveyors are designed with Stainless Steel construction and are built to food or pharmaceutical industry and plant specific needs as dictated by your sanitation or food safety requirements. Designed to fit your company’s unique processing application, we will ensure you get exactly what you need.

The country's leading food manufacturers seek our our sanitary products because we understand the need effective, easy-clean, hygienic and wash down conveyors, all of which are high priority for Multi-Conveyor. We take the same approach when it comes to providing our customers with UL certified controls design and UL approved equipment.

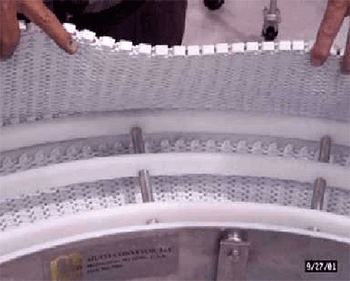

Most agency food-grade compliant designs (USDA, WDA, AMI, FDA, 3A, meat, dairy, BISSC, etc.) are available on request. Several frame designs have a variety of features such as clean out ports, spray nozzles, lift up belt, lift out carry way and return way. Standard sanitary conveyor features include spaced off frame components, sanitary supports and washdown resistant power transmission components.

Increased throughput, along with elimination of product waste and downtime, are essential in providing a quality conveying system to our customers. New product carrying belts or chains, and materials for wear parts, must add to the performance criteria of a project, while meeting guidelines for materials acceptable in the beverage/food or pharmaceutical industries. Conveyor construction should be resistant to chemicals used in cleaning and sanitation. Often times all of those characteristics are required of each conveyor.

Although far too many to mention, critical points may include:

√ Removable NTR (no tool required) components for cleaning.

√ Gasketed areas to keep contaminants from getting behind wear strips.

√ Critical radius welds and radius bushings.

√ Tooless removable CIP's (clean in place).

√ USDA approved urethane belts for tight transfers.

√ Plastic washers behind all fasteners.

Whether your needs are for raw product handling, flexible packaging, fresh and frozen products, bakery or snack foods, case packing, robot feeding or any other manufacturing process, we have excellent food processing conveyors and solutions. No project is too small or too big, including full turn-key systems that incorporate mechanical, electrical controls that interact with your equipment.

If you do not require wash down conveyor systems, click here to learn about our Mild Painted Steel Constructed systems.

Key Components of our Sanitary Systems include:

- Stainless Steel Construction Built to Industry Design Standards

- Built to the Customer’s Sanitation & Safety Needs

- Application Driven Designs

- Agency compliance as directed

- Washdown systems as needed

All of our conveyor systems and equipment are factory acceptance tested right here at Multi-Conveyor, either with you or your assigned representative present, before it leaves our floor. In your plant “de-bugging” and “fine tuning” are always available, if required, providing you with the most reliable piece of equipment available.