posted on June 24, 2022 08:48

The Case for Chain Drift Parallel Transfer

… including simplistic 2:1 combiner.

Multi-Conveyor (Winneconne, WI) - Multi-Conveyor recently built a high-level hygienic 48” wide, flush grid and side flexing plastic conveyor belt solution to replace an existing wire belt system – while satisfying the customer’s need for a far more sanitary constructed conveyor in the process.

Product discharges in multiple lanes from the customer oven to the Multi-Conveyor infeed. Rows uniformly convey through a slight incline then end transfer to a side-flexing 35° curve which maintains orientation required for accurate spacing and placement for the freezer infeed ahead. The upgraded belting provides a much smoother transition in product transfer areas.

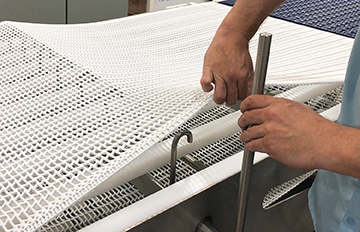

Integrated belt-lifts were requested for ease of cleaning and maintenance. Chris Jeszke, Project Manager, explains … “The integrated belt lift allows customers to access and clean underneath the chain without having to remove the chain.” The manually operated belt lifts were strategically placed.

Clean out holes or ports are also incorporated in specific locations to allow the operator visual assistance in the belt cleaning process. These viewing areas are common in hygienic constructed conveyor systems.

Clean-in-place (or CIP) systems typically include other sanitary features, as Chris continues … “And for our chain clean-in-place, we offer a drain pan that has a threaded fitting that can be attached to the drain so that no water or anything contaminates the floor or area around the conveyor.” The drain pans span the entire width of the conveyor in several locations, along with respective CIP fittings.

Removable wear strips were key to this project. Yet, they had to be secured during operation. Chris demonstrates Multi-Conveyor’s simplistic solution … “In order to retain the upper wear strips, we have pins to secure them in place. They’re easily removable and captured,” Chris finishes. Just like the other features, the removable wear strip pins were specifically placed for optimum accessibility.

The portable stainless steel constructed system met or exceeded all sanitation construction levels for the customer’s regulated agency compliance mandates.

About Multi-Conveyor

Multi-Conveyor is a leading manufacturer of both pre-engineered standard and uniquely designed custom conveyor solutions for CPGs, End-Users, Integrators, Engineering firms, Automation/Robotics, AI, OEM's and Contract Packagers across multiple markets. Our products are multiple and unique. No single conveyor product defines Multi-Conveyor. We specialize in conveyor systems for packaging or material handling for nearly every industry, product, shape and size. Our customers report they select Multi-Conveyor for concept/design, engineering skills, quality product, best value and prompt delivery.

Watch this brief video with narration for further information: https://youtu.be/6gMw5cayBj0