The Evolution of Conveyors in Food Manufacturing

Applications in meat and poultry, seafood, baking, confections, fruits and vegetables, prepared foods, frozen food, organics, cannabis infused, pet food and dairy-based products have all benefited from the newly developed conveyor designs.

As food and beverage manufacturing grew into the 20th century, the use of conveyors was initially thought of as a transport method but has evolved to be an integral part of producing large quantities of food to supply an ever- growing population. It became evident that there was a need to streamline the handling of food ingredients or products while utilizing drums, containers, pails and mixing equipment but the manpower required was holding back growth. Although the use of conveyors was initially thought of as a transport method, they have evolved to be an integral component to produce larger quantities of food at quicker line speeds.

The first conveying equipment was made of steel, aluminum, wood or whatever someone could muster up to do the job. Use of cotton belting was quite common as it was cost effective and readily available. Eventually, belt providers developed methods to laminate covers made of a variety of resins that allowed for cleaning the surfaces. Although this was a major step in improving the quality and sanitation, it wasn’t until the introduction of new synthetic materials which allowed for better cleaning surfaces, strength and flexibility.

Today’s 21st century food carrying conveyors have come a long way from inception. Applications in meat and poultry, seafood, baking, confections, fruits and vegetables, prepared foods, frozen food, organics, cannabis infused, pet food and dairy-based products have all benefited from the newly developed conveyor designs. But along with the benefits come capital expense, maintenance, repairs and even replacement, let alone government compliance and stringent requirements from food retailers.

Cleaning and Compliance

Food processing applications that store, elevate, transfer and maintain patterns for downstream packaging in many cases are being utilized 24-7. Continuous handling of the raw products can (sometimes) create unsanitary conditions, especially as product line demands outweigh the need or time required for regular cleaning and maintenance.

Food processing applications that store, elevate, transfer and maintain patterns for downstream packaging in many cases are being utilized 24-7. Continuous handling of the raw products can (sometimes) create unsanitary conditions, especially as product line demands outweigh the need or time required for regular cleaning and maintenance.

Changing of shifts, crews, contract cleaning services and construction are some of the issues requiring special attention to maintain sanitary operations. Numerous times, the handing over form one shift to another creates inconsistent conditions.

When agency inspectors arrive, management should welcome any reports indicating non- compliance as an incentive for personnel to adhere to the sanitation standard established and immediately comply to correct the issues. These reports are also instrumental in the design of future equipment, to make sure it's agency compliant from inception.

Belts are usually fastened at each end with a variety of techniques. Belt splicing is done in a variety of methods from hot vulcanization, cold vulcanization or mechanical splicing. Usually endless hot vulcanized belts last relatively long, however, once they require repair or replacement, the conveyor design becomes critical.

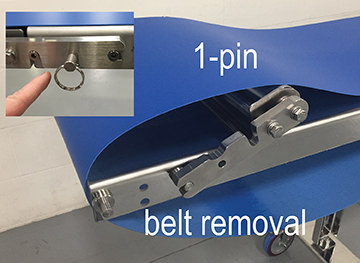

Many newer designs allow for the complete disassembly of the conveyor for cleaning using the NTR (no tools required) approach. These designs promote time-saving belt cleaning, repair or replacement.

Many newer designs allow for the complete disassembly of the conveyor for cleaning using the NTR (no tools required) approach. These designs promote time-saving belt cleaning, repair or replacement.

NTR belt removal takes mere seconds/minutes, allows for easy maintenance and simplistic changeovers, alleviates unnecessary toolboxes and tools for increased operator safety. The tool-less pin-pull approach allows the operator to remove the belt in mere seconds for routine maintenance.

Belt cleaning and inspection lifts are a useful addition and are simple in design. Additionally, lifting the belt from the bed section allows the belt to air dry if conditions allow, otherwise, belt cleaners are commercially available. Spray heads are another option which can use heated water if necessary to clean the top surface and bottom sides of the conveyor return path. More sophisticated belt washing systems may include dryers and programmed cleaning cycles with duration options.

One method to simplify the vulcanization process utilizes an added length of belting for cases where splices fail or a section becomes damaged. This "loop" allows storage of additional belting within the belt path itself, whereas the maintenance person can cut out a section and prepare a new splice point for vulcanizing or splicing.

One method to simplify the vulcanization process utilizes an added length of belting for cases where splices fail or a section becomes damaged. This "loop" allows storage of additional belting within the belt path itself, whereas the maintenance person can cut out a section and prepare a new splice point for vulcanizing or splicing.

Depending on the location of the conveyor, it is possible to require sufficient lengths to drop the loop to floor heights. The ability to repairing a belt save the cost of a new belt when only a splice has failed.

Depending on the location of the conveyor, it is possible to require sufficient lengths to drop the loop to floor heights. The ability to repairing a belt save the cost of a new belt when only a splice has failed.

Removal rollers are essential for dry applications. Trough conveyors are commonly preferred in food processing applications. Super sanitary trough conveyors combined with urethane belting form a "U" or trough-shape for product stability to move fine or raw food product on inclines or pitches.

The Introduction of Modular Plastic Belting

The 70’s were instrumental years for numerous developments in plastics for conveying applications. Once used in canning, bottling and harsh environments, flat top chains were previously made of steel or stainless steel. Developed to minimize line pressure and line lubricating with soapy water, plastic flat top chain became widely used. Plastics applied to the carrying surfaces, or wear strips, reducing the friction and allowing for longer lengths and flex became an entirely new segment in conveying. From this design came the development of a mat style belt which would be modular in design allowing for various widths and lengths and compositions.

These modular belts have replaced many steel belts, fabric belts and synthetic belting due to the many advantages they offer from life expectancy, cleanability and ease of repair and replacement. Some providers offer an array of molded flights (links) which can provide lift, indexing, identification, product containment and numerous applications for automating production lines.

A more recent development in sanitary design is the continuous belt which includes tracking and friction driven carry sides. These belts are sometimes offered in a turquoise color which has become popular for this belt design, as well as synthetic flat belting, giving an advantage of the ability to identify particulate in contrast to the more common “blue belt”.

Conveyors may require features such as clean out ports, spray nozzles, belts lifts, and easily removable carry way and return way components. Standard sanitary features should include standoffs for frame mounted elements, sanitary supports and wash down rated power transmission components.”

The design of the conveyors should be void of ledges, shelves, crevices, hollow cylinders and generally be capable of allowing the design to free itself of contamination with normal care. While some applications require a more rigorous method, such as meat, poultry, fish processing and hard to clean products, many conveyors require extreme cleaning for presence of allergens, sometimes requiring belts to be completely removed and sanitized remote to the conveyor. Simply because a facility has strict requirements in the plant and simply because your site appears to meet your standards doesn’t stop the Infestation to roam when “the lights are off and nobody is home".

Plan For The Latest Advancements in Sanitary Packaging

All of these advancements lead to sanitary packaging. Most production lines are running various size containers, packages and alternating products on the same system. These days engineers and plant managers need to specify conveyors that adapt to multiple products on one line. This may include variable line speeds, changeovers, elevation changes, twists, turns, diverts, redirects, indexing, sorting, merging and much more ... all while moving in the direction or process required.

All of these advancements lead to sanitary packaging. Most production lines are running various size containers, packages and alternating products on the same system. These days engineers and plant managers need to specify conveyors that adapt to multiple products on one line. This may include variable line speeds, changeovers, elevation changes, twists, turns, diverts, redirects, indexing, sorting, merging and much more ... all while moving in the direction or process required.

Flighted inclines, declines, elevators, lowering conveyors and other package- processing systems are also becoming more popular - especially when shipping large volume or e-commerce direct food-to-table products. Elevation in conveyors can lower the overall production line footprint of your processing operation, opening up critical space on the plant floor.

Key factors to consider with any conveyor system are agency compliance; safety; ease of use; maintenance; longevity; sanitation; quality components and how to meet or even exceed the application’s initial requirements; along with after-sales service, parts and warranty.

Conveyors are the lifeline component that keeps your products moving. When sourcing out your next food grade, sanitary or washdown conveyor system, make sure you're keenly aware of the newest technology, quality of construction and system performance.

▷ Download The Evolution of Conveyors In Food Manufacturing White Paper ◁

Editorial Contributions

John Patois of Patois Associates

John has been engaged in the packaging, processing and materials handling industry since 1974. Initially in materials handling, his knowledge expanded into the packaging and processing area with numerous food, baking, beverage and dairy clients. Mr. Patois remains a sales and marketing consultant, currently residing in New Jersey.

Jim Paulsen, Sales Account Manager

Cheryl Miller, Director of Marketing

How can we help you with your next food conveyor? Find out. Call now 1-800-236-7960